K2TEC provides solutions for the Food and Beverage Industry

Home > Applications > Food and Beverage

Industrial Liquid Filtration for the Food and Beverage Industry

The industrial filtration of food and beverage is a critical step for many processes or for the treatment of food processing waste.

The agri-food industry includes many activities and multiple actors, from small businesses to multinationals. For the leading industrial employers in France and in the world, it is a high-standard activity that requires respect and compliance with standards, rigor, innovation, and competitiveness.

Filtration plays a key role in maintaining food processing equipment, keeping food and beverages fresher and prolonging their shelf life.

Food processing filtration: in the food industry, this type of filtration and the use of process filters are an essential step. Eliminating particles in liquids whose viscosity is as variable as water or honey, including dough, sauces, chocolate, compotes, jams or surimi is a crucial operation, delicate and sometimes complicated.

Safety filtration: food products often require safety filtration, before being mixed or packaged. This operation eliminates polluting particles that may have arrived accidentally in the manufacturing process: lumps, skins or hulls, but also plastic particles, corks, metal particles, bolts, screws, small pieces of gaskets, etc.

Water filtration in the Food Industry: water is used in many ways: for washing, for cooking or cleaning installations, it can also be incorporated into preparations at different stages. Whether it is used in a closed circuit or intended to be discharged and sent to a treatment plant, water in the food industry must meet very precise standards, hygiene and purity levels.

Do you have a filtration inquiry ?

K2TEC offers a complete family of filters, in compliance with CE and FDA standards, to meet the hygiene and safety requirements of the diversity of players and products within the food industry.

This stainless steel filter was created to answer one of the most challenging demands of the food industry: the filtration of viscous foods.

The PLM automatic self-cleaning filter has been specifically designed for the filtration of medium to high viscosity products. Making it ideal for liquid industrial filtration in the agri-food industry.

The filter is used for caramel filtration, chocolate filtration, surimi filtration, sauces filtration, mayonnaise filtration, ketchup filtration, compote filtration, pancake batter filtration, tomato paste filtration, gelatin filtration.

The PLM automatic self-cleaning filter can be used for the filtration of food products without requiring consumables, in a closed chamber and free of contamination risks.

This simple and solid 304 or 316L stainless steel filter is used in multiple processes of industrial liquid filtration in the food industry.

For food processing applications, our KBF stainless steel bag filter housing can receive different types of treatment, e.g. surface treatment. Bag filter housings can be left untreated after passivation, but most of the time the bag filter housing is either electro-polished or manually polished with a controlled roughness index that can be reduced to an RA 0.2 if necessary.

The KBF bag filter housing in stainless steel for the food industry is ideal for filtering: fruit juices, oils, infusions, water, and more.

We provide our filter bags to be used with these bag filter housings.

For the food industry, K2TEC also offers a range of filters and single-use or reusable filter elements that will meet our customers’ demands.

The filter bag is a simple and effective solution for the filtration of food liquids. It is reliable and versatile to be used in a variety of filtration applications in food processing, such as juices of all types to remove pollutants including lumps, dry particles, insects, seal debris, etc.

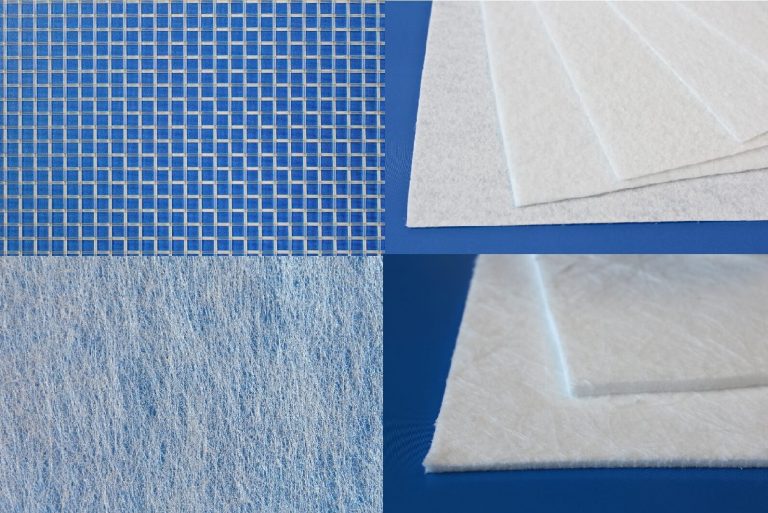

Filter bags can be made in different materials: monofilament for applications that may require recirculation with filtration rates from 1 micron to 2000 microns, felt or multilayer for the filtration of liquids from 0.5 microns to 200 microns.

Considering the variety of applications in the food industry, K2TEC can supply rolls of filter fabrics. We have different types of filter fabrics to choose from: precision filter fabrics, filter cloths and non-woven filter fabric. Filtration rates can range from 1 micron to 4000 microns.

If required, K2TEC can also cut and shape these products according to your needs to create filter elements that can be integrated into your process.

Custom filter elements for the food industry are made from our filter fabrics, such as filter press cloths, that are widely used in the wine, beer or edible oil production processes.

Custom filter elements are used in different sectors within the food industry. K2TEC manufactures hopper cloths used in bakeries as well as various transportation or conveying, blowing and filtering parts.

Filter paper rolls are generally used for the filtration of cooking oils and can also be employed for the filtration of low-viscosity juices or gelatins.

They can also be used for applications in our great specialty: press belt filters or process vacuum belt filters.