viscosity...

what viscosity ?

Home > Filtration techniques > Viscosity

Viscosity in industrial filtration

Viscosity is a measure of a fluid’s resistance to flow. This notion may seem simple but the measurement of viscosity can quickly become complex to explain and especially to communicate. Let’s analyse the impact of viscosity in industrial filtration.

What is viscosity?

To keep it simple and especially to avoid getting lost in mathematical theories, we will put viscosity in industrial filtration and solid-liquid separation into perspective.

In this small article :

– we will provide elements of conversion of the units of viscosity.

– we will give some viscosity reference points on common products.

– we will talk about the 2 friends of viscosity which are the flow rate and the filtration rating.

– finally we will tell you about our automatic, manual or semi-automatic filters for low, medium and high viscosity products.

Do you have a filtration inquiry ?

Viscosity and filtration rating

Filtration means filter media, filter media means obstacle and obstacle means flow resistance.

The finer the filter media, the more difficult it will be to make a viscous product pass through it, whatever the nature of the filter (stainless steel or synthetic material). The material of the filter changes little or not at all. The structure of the filter has an impact.

The more viscous a product is, the more complicated it is to get it through a filter. To simply illustrate this notion, imagine the speed of water passing through a strainer and imagine the speed of honey.

Viscosity and flow rate in industrial filtration

A viscous product presents several challenges. Its high flow resistance requires pumps able to cope with it (membrane pump, peristaltic pump, lobe pump, etc…) and the pipe diameters are also larger.

The same applies to filters. At the same flow rate, a viscous product will need a larger filtration surface and therefore a large filter.

Viscosity and choice of an industrial filter

To determine the type and size of an industrial filter, viscosity is one of the most important components, along with flow rate, filtration rating and contaminant load.

Viscosity can also be difficult to determine. Indeed, even for identical products, viscosity fluctuates according to temperatures, fillers and raw material ingredients.

For high viscosities (above 10’000 centpoise), synthetic filters have their limits (tearing, bursting) and it is necessary to use stainless steel filters. To make a price quotation, K2TEC provides a technical questionnaire which allows an expert, according to the different parameters, to suggest a suited filter.

Viscosity units in industrial filtration

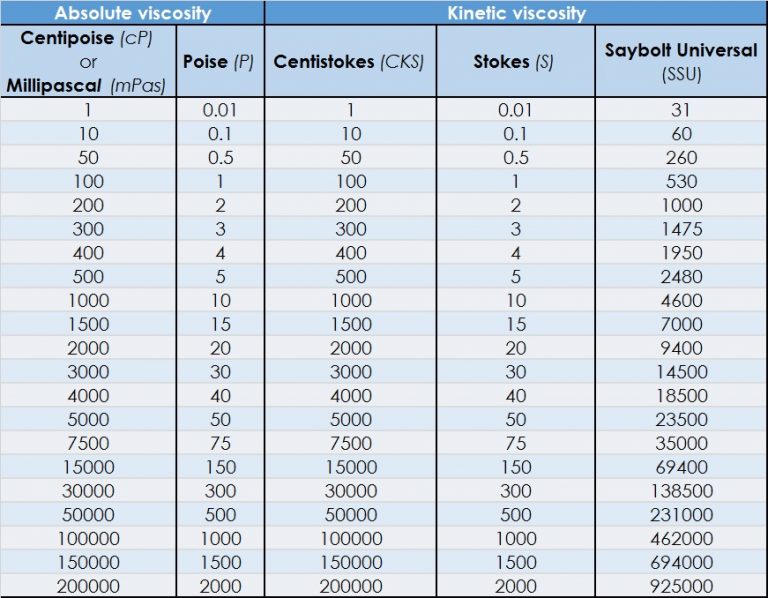

Even if viscosity values are more and more expressed in Poise and Pascal, “old units” such as cups (Iso, Ford, Afnor…) are still used… The viscosity of oils is expressed in numbers and letters whereas the viscosity of paints is regularly expressed in cups.

To help you, here is a small summary of the conversions of the viscosity units and an exhaustive correspondence table.

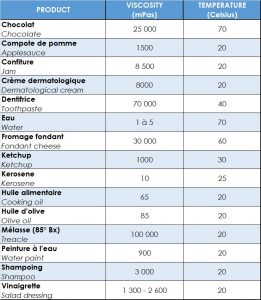

Examples of viscosity of common products

How to filter low-viscosity products?

The PNT gravity filter is able to handle very large flow rates, up to 50 m3 /h with low viscosities. It is not very sensitive to variations in viscosity, load and flow rate, thanks to a float that automatically triggers an advance of clean non woven filter when it is saturated.

The applications are the filtration of products such as oils, emulsions, water of various kinds (process, discharge…).

How to filter medium viscosity fluids?

For varnishes, industrial paints, chemicals and other liquids up to 5000 cP, the KBF bag filter is a simple, efficient and flexible industrial filtration system. With a simple change of the bag, filtration ratingd from 1 micron to 2000 microns can be changed in a few minutes.

This closed filter operates under pressure and is very versatile. It is available in 4 sizes and can be multiplexed for flow rates up to 300 m3/h.

The bag filter is also efficient for the filtration of low viscosity products, or it offers a less bulky solution than the PNT gravity filter.

How to filter high-viscosity fluids?

The PLM automatic self cleaning filter starts when all others stop. This means that this extremely robust, simple and efficient filter finds its applications when the gravity filter or the bag filter are not able to filter.

We are talking about high viscosity products such as coatings, glues, silicone, effect paint, chocolate, PVC slurry, dough, starch, surimi paste…

Up to 150,000 cP: the PLM filter never gives up and above all resists with a clever, robust and ecological French engineering and it does not need any consumables.