Home > Filter elements > Filter bags

Filter bags for industrial filtration of liquids

Filter bags are one of the most commonly used and economical filter elements for the filtration of liquids. They are used in bag filters, both for batch filtration and for high flow filtration.

K2TEC has been designing and manufacturing industrial filters for solid/liquid separation for more than 30 years.

K2TEC offers standard filter bags and is also able to design custom-made filter bags to meet the most demanding requirements.

Highlights of K2TEC filter bags

35 YEARS

of experience in industrial filtration

MATERIALS

Felts and monofilament fabrics, available with food grade certification

FILTRATION RATINGS

0,5µ to 2000µ

PRODUCTION

standard bags and also

fully custom made

Range of filter bags

Find detailed information on each filter bag by clicking on “LEAR MORE”.

Do you have a filtration inquiry ?

DETAILED INFORMATIONS ON K2TEC RANGE OF FILTER BAGS

In order to answer many industrial filtration applications, K2TEC has developed a range of products to meet all demands

Standard filter bags

K2TEC manufactures filter bags for standard bag filter housings and special filter vessels. Standard filter bags are stitched. The materials used to manufacture the filter bags have been chosen for their consistent quality and performance. We offer a comprehensive range of materials to suit even the most demanding applications.

All K2TEC filter bags are guaranteed to be silicone-free to minimize any possible contamination. These filter bags are manufactured with the highest standards to ensure reliability and reproducibility over time.

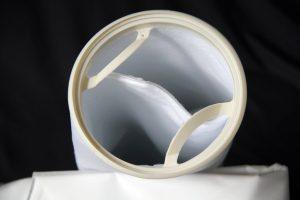

Standard filter bags are available with several seal ring options: galvanized steel, stainless steel and molded plastic seal ring.

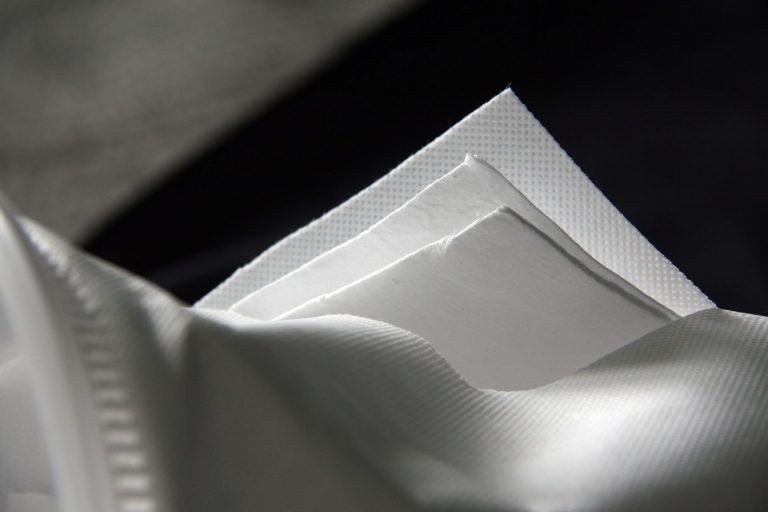

Fully welded filter bag

A fully welded filter bag increases filtration efficiency.

To meet the most sophisticated requirements in terms of efficiency and micron rating. K2TEC relies on ultrasonic welding to remove the seams from the filter bags.

Welding the bags together eliminates possible preferential passages through the needle holes that may occur during stitching (useful for the lowest mesh opening).

The manufacturing process by ultrasonic welding does not require the addition of any external material. Therefore, these filter bags are guaranteed to be silicone-free.

The molded seal ring for the filter bags, made of polypropylene or polyester, is also welded, forming a hermetic seal between the filter housing and the filter bag.

These characteristics make welded filter bags more efficient than stitched filter bags.

Welded filter bags are available in polypropylene and polyester felt, as well as high performance and long life felts.

High capacity filter bag

The high capacity filter bag has an additional 70% filtration area.

This high capacity filter bag is manufactured with two filter fabrics cylinders: the classic outer part of the filter bag (Ø 180 mm), and an inner part (Ø 120 mm). This construction increases the filtration surface area by 70% compared to a standard product.

The increase in the filter area retains a greater quantity of undesirable particles, extends its service life and increases the admissible flow rate.

Thanks to this double configuration, the filter bags have 70% more filtration area while occupying the same volume. Therefore, they contain a smaller liquid volume. As a result, high capacity filter bags are significantly lighter. A high capacity filter bag is only 25% of the weight of a standard bag when filled with liquid, making it easier to change. The volume of product lost decreases too, which can generate significant savings in the medium term.

These high capacity filter bags are used with special baskets to support both the external and inner parts. These special baskets can be installed at any time in standard filter housings without any modifications. This increases the performance of a bag filter at a reduced cost.

These high capacity filter bags are manufactured with our molded plastic rings to maximize the sealing between the bag and the filter housing. They are available in sizes 1 and 2 and manufactured with different filter fabrics, such as felt or needlefelt, monofilament mesh, precision woven synthetic fabrics, and more.

Food and pharmaceutical grade filter bags

Filter bags for the filtration of food and pharmaceutical products must comply with European standards for materials in contact with foodstuffs.

Manufacturing, storage, and packaging conditions must be carefully controlled to eliminate all possible sources of contamination. K2TEC’s filter bags have been specially designed and engineered to meet all these requirements.

The materials used for food and pharmaceutical grade filter bags have been selected for their quality and traceability, ensuring efficient and safe filtration. They comply with the EC 1935/2004, EC 10/2001 and FDA Title 21 standards.

We also provide compatible rings for food-grade filter bags, such as polypropylene molded rings and stainless steel rings.

The outer surface of the felt filter bags is calendered, eliminating any possible migration of fibers into the final product.

Each filter bag is individually packed, and the manufacturing process meets ISO 9001-2000 standards.

Filter bags for the food industry are normally used in so-called “sanitary” bag filter housings made of 316L stainless steel, with internal welds, surface finishing, etc.

Extended life filter bags

Extended life filter bags are used when changing the filter bag is difficult or risky.

Extended life filter bags use special filter media. These polypropylene or polyester filter media are available with micron ratings from 0.5 to 100μ and increase the life of the filter bags up to five times compared to a traditional bag.

The density of the filter media is progressive, the coarser particles are captured at the surface and the smaller particles pass through the different layers or “thicknesses” of the filter bag, thus preventing rapid clogging. The higher thickness of this filter media allows the filter bags to retain a larger quantity of particles.

These high capacity filter bags are clogged at a slower rate, and can, therefore, increase their service life by up to 5 times compared to a standard filter bag.

These filter bags are completely welded, preventing fluid leakage through the stitchings. The outer part of the filter bags is calendered to eliminate any potential risk of fiber release.

Multilayer filter bags

Multilayer filter bags have an efficiency of over 90% and can incorporate up to 4 layers of filter media for micron ratings from 0.5µ to 25μ.

Multilayer filter bags are high-efficiency products, available from 0.5μ to 25μ with a performance above 90%. They are designed for critical applications that require superior filtration performance. These filter bags are manufactured in polypropylene non-woven fabrics and can be made of up to 4 different layers. These filter bags are also available in polyester for temperatures above 100°C or when polypropylene is not chemically compatible.

Combined with our polypropylene molded seal ring, multilayer filter bags can be fully welded. As a result, any contamination related to needle punctures during stitching is eliminated. Each layer of the product is individually welded to ensure greater mechanical strength. Multi-layer filter bags are also available with rings in galvanized steel or stainless steel for custom bags.

High efficiency filter bags

High efficiency filter bags are made of polypropylene and microfiber polyester composites. Retention efficiency ranges from 90% to 99.98% for our full range of products.

These high performance filter bags are used for critical applications with contaminants loaded fluids, that require very fine filtration, working with micron ratings ranging from 0.2μ to 25μ.

For a long time, filter cartridges have been used in industries such as pharmaceuticals, automotive, chemicals, food and beverages, drinking water, cosmetics, electronics, etc., for their ability to retain fine unwanted particles.

Nowadays the use of high efficiency filter bags has proven to be superior in terms of service life, ability to retain a larger quantity of unwanted particles while maintaining or increasing the filtration efficiency at a lower operational cost.

Areas where high-efficiency filter bags can replace cartridges are numerous, such as membrane protection on reverse osmosis processes, carbon filtration, filtration of critical fluids, etc.

Alternatively, these high efficiency filter bags can be used as pre-filters to extend the life of very expensive absolute rated filter cartridges. High efficiency filter bags can also be manufactured with materials compliant with European directives for food contact products, and also with FDA standards.

Filter bags with string

Filter bags can be made with tightening strings. They can be installed directly at the piping outlet without needing a special filter housing or adapter.

These filter bags are intended for filtration applications that work with low pressures and where open filtration is acceptable. They are an economical alternative to the filter bags used in filter housings.

Filter bags with strings are sewn, the stitchings can be reinforced for fragile filter fabrics.

Theses filter bags are mainly made of monofilament fabrics because these soft fabrics make tightening easier. They can also be made in other materials such as felt (needlefelt).

Special filter bags

Before manufacturing standard filter bags, K2TEC, who has been involved in the field of industrial filtration since 1989, was already manufacturing special filter bags.

Some innovative or confidential liquid filtration processes require specific products: pharmaceutical laboratories, the nuclear industry, army, automotive…

K2TEC can develop a tailor-made solution with its design office or work on plans and specifications to offer ready-to-use products

that meet customer requirements in terms of dimensions, materials, support and all types of special requirements .

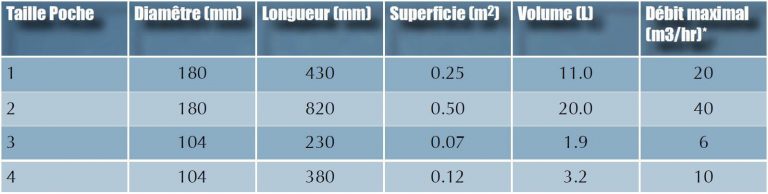

Dimensions of standard filter bags

Chemical compatibilty of filter bags

Filter bag materials

K2TEC offers different materials for the manufacture of filter bags. They are chosen for their filtration quality and comply with the standards in vigour: REACH, CE and FDA food certification, etc…

Felt and non-woven

Felt or needlefelt filter bags are versatile and come at a moderate cost. Effective on solid and deformable particles, they offer deep filtration.

They are available in several materials: polypropylene, polyester, polypropylene with extended life, polyester with extended life, nomex…

Filtration ratings from 0.5 to 200µ. Food-compliant filter bags: Food-contact certificate available on request.

Monofilament precision fabrics

Monofilament fabrics make for high-precision and very stable filter bags, available from 1 to 2000 µ in Nylon, Polypropylene (PP), Polyester (PES) ,PTFE, and more.

Special filter fabrics

For special filtration applications, filter bags can be manufactured in non-woven materials, multilayer materials, absorbent materials, coated fabrics, antistatic fabrics, etc.

Types of seal rings

The filter bags with galvanized steel and stainless steel rings fit universally into all standard bag filter housings. Available in standard diameters 105 and 180 mm and special sizes.

Filter bags with welded polypropylene or polyester molded rings are designed to ensure sealing, eliminate needle punctures during the sewing process and are equipped with handles for a quick and easy installation and replacement. They can also be inserted in our standard or custom KBF bag filter housings.

Polypropylene moulded rings are incinerable and make it possible to recycle used filter bags. Available in standard diameters 105 and 180 mm.

Polyester moulded rings are intended for applications with high temperatures or where chemical resistance properties are required.

Applications of filter bags

These K2TEC filter may interest you :

Custom filter elements

Design and manufacture of custom-made synthetic filter elements for the automotive, medical, household appliances, acoustics, aeronautics…

KBF Bag filter housings

Range of stainless steel bag filter housings. K2TEC specializes in filter vessels and filter bags, providing the best solution for liquid-solid separation.

Precision filter fabrics

Precision woven filter fabrics and mesh filter fabrics. An overview of our range of syntethic fabrics for appliance and industrial filters.