Home > Industrial filters > EVO Self cleaning strainer

Self cleaning strainer PLM EVO for highly viscous and abrasive products

The PLM EVO is a self cleaning strainer with dual actuators, entirely made of 316 L stainless steel. This scraper filter is an ecological filtration solution, as it works without consumables. It has a superior capacity to filter medium to very high viscosity industrial products.

Particularly effective to process industrial liquids for the following industries:

- Food industry: such as dough and pastries, sauces, jams, chocolate and more.

- Chemical industry: chemical fluids, polymers, abrasive products.

- Paints and coatings: metallic paints, abrasive paints.

- Automotive sector: automotive paint filtration.

The ease of cleaning also makes the PLM EVO a particularly popular filter in the:

- Pharmaceutical industry

- Cosmetic industry

The PLM EVO sealf cleaning strainer is the evolution of our original PLM filter. At K2TEC we have completely redesigned our original filter to increase its efficiency for the filtration of highly viscous products.

This new generation of automatic scraper filter is equipped with two actuators to increase its scrapping power.

We have completely rethought and redesigned the cleaning and access to the stainless-steel filter screen. It can be performed directly from the bottom of the unit without the need to disassemble/remove the filter head.

The sealing has been reengineered to better resist abrasion and to be easily replaced.

The PLM EVO strainer keeps all the advantages of its predecessor: a 316L stainless steel vessel, simple and solid construction that gives it outstanding performance in many industrial filtration processes.

And of course it is zero waste: zero bags, zero cartridges and zero consumables.

This automatic self-cleaning strainer can be controlled by a dedicated control cabinet and/or connected to a monitoring system.

The performance of the PLM EVO self cleaning strainer

The performance of this self cleaning strainer depends on the flow rate and viscosities of the products to be filtered. Its technology allows this type of automatic filter to handle large flow rates in duplex or triplex systems.

from 25 microns to 2000 microns

up to 250 000 cP

from 5 to 35 m3 / unit

(multiplexing is possible)

zero consumables

no bags | no cartridges

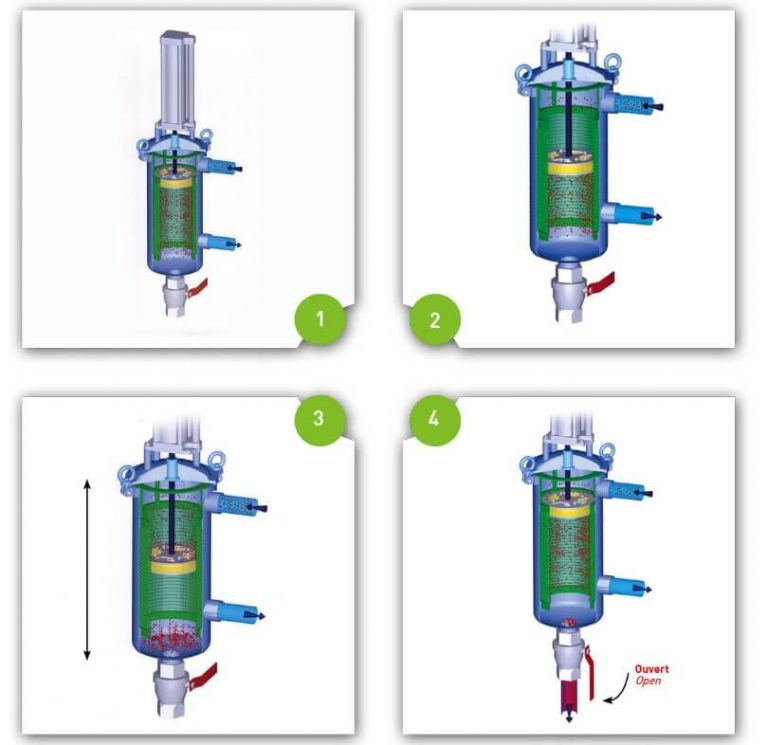

Operation of the automatic scraper filter

- The product to be filtered enters from the top of the automatic scraper filter. The fluid passes through the filter element, depositing unwanted impurities on the surface of the filter screen. The clean liquid passes through the filter screen and exits through the outlet.

- The solids that have been accumulated on the filter screen are pushed to the bottom of the filter housing by a scraper, which can be controlled by a timer or by measuring the differential pressure.

- At the bottom of the filter housing, the unwanted solids pushed by the scraper are waiting to be evacuated. The flow of the liquid prevents these solids from flowing back into the filter vessel.

- Those impurities accumulated in the lower section of the filter body are either removed by controlled “flushes” (pneumatic valve or solenoid valve) or manually, without interrupting the flow rate.

Advantages of the automatic scraper filter EVO

The automatic scraper filter EVO has been designed for the filtration of high viscosity and/or abrasive products.

It offers many benefits compared to other filter technologies.

Like all PLM filters, the series of EVO filters are completely automatic and self-cleaning. They can be controlled by a dedicated control box or connected to a general monitoring system.

This automatic scraper filter uses a simple and reliable concept for cleaning the filter surface. The scraper wipes the stainless-steel filter screen and pushes down all the impurities towards the bottom of the filter vessel.

Like our traditional PLM filters the stainless steel filter screen can be cleaned during the process, without interruption or loss of flow thanks to the controlled scraper system that provides an automatic filter cleaning.

The stainless steel filter screen is extremely resistant and the filtration rating changes neither over time nor when the surface is clogged. After cleaning, the flow rate returns to its nominal value.

The filter does not use any consumables (filter cartridges or filter bags), offering an environmentally friendly filtration. When clogging occurs, it generates a minimum product loss, since only the pollutants are evacuated through the bottom of the filter housing thanks to a manual or automated purge.

This new filter model has been designed for companies working in batches or performing frequent disassembly or cleaning. The opening of the bottom facilitates access to the filter screen, the scraper and the main vessel. The filter can also be tilted to simplify maintenance operations.

With two pneumatic actuators in twin assembly, the Evo automatic scraper filter is capable of processing products with extreme viscosities. The twin mounting of the actuators facilitates the access to the filter gaskets.

The PLM EVO uses a quick-release stuffing box. For abrasive products, the service life of the main seal has been significantly improved. When the seal shows the first sign of wear, the stuffing box can compress the seal several times before needing to be replaced.

Options for the self cleaning strainer

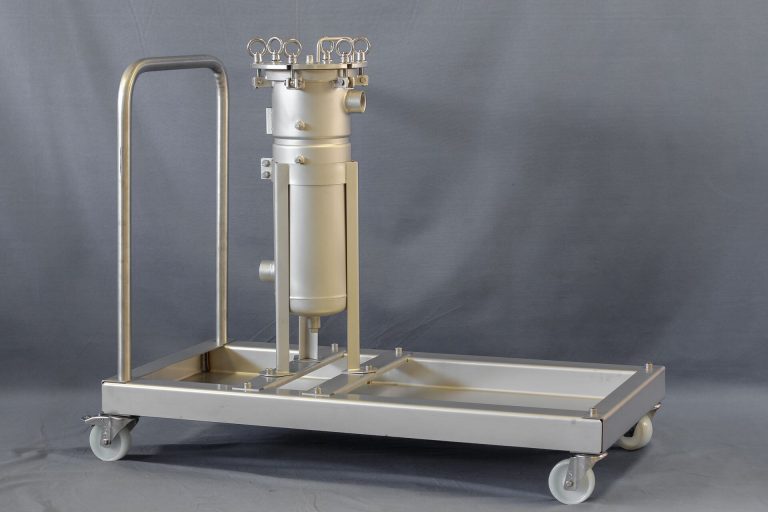

The PLM EVO filter is manufactured in France, allowing multiple options such as the type of connections for inlets and outlets, the stainless steel surface finish, different levels of automation, and more. Our design office can also create a tailor-made solution for the filtration skid.

Control box

The PLM EVO filter is available with different levels of automation for the automatic cleaning process. Our engineering and design department can include a control panel with a PLC to control the scraping and purging cycles with a timer, or even more complex panels to monitor the cleaning process by monitoring the differential pressure measured by pressure sensors.

Engineering and design office

K2TEC’s integrated engineering and design office specializes in offering tailor-made solutions to integrate the mechanically cleaned filter into your process. K2TEC can craft a custom quotation for your approval before the production process. Several manufacturing parameters can also be adapted.

Stainless steel filter screen

The filter screen is made of high-precision 316L stainless steel trapezoidal wire. This stainless steel wire is carefully welded to guarantee a precise filtration rating. Its trapezoidal shape guarantees that the surface of the filter element will not clog.

The standard micron ratings are 25 µm, 50 µm, 75 µm, 100 µm, 150 µm, 180 µm, 230 µm, 300, µm, 380 µm, 500 µm, 800 µm, and 1000 µm. Other ratings are available on request.

Surface finishing

All of the PLM EVO mechanically cleaned strainer, like the entire PLM filter range, are manufactured in stainless steel and available in different types of finishes: passivated, bead-blasted, electro-polished or manually polished depending on the process requirements.

Inlet, outlet, and drain fittings

K2TEC offers several types of inlets and outlets such as male or female threaded fittings, tri-clamps, flanges, cam locks, SMS unions, etc.

ATEX certification

K2TEC can provide ATEX II 2G II c T4 certification for the PLM EVO automatic scraper filter for operation in hazardous areas.

Applications of the mechanically cleaned strainers

The PLM filter range is ideal for applications where viscosity causes problems for conventional filters such as bag filters or cartridge filters. The EVO series also provides better performance for abrasive products and easier maintenance for batch processes.

Filter skids

Filter skids and mobile industrial filtration systems for bag filter housings and automatic self-cleaning filters.

KBF Bag filter housings

Range of stainless steel bag filter housings. K2TEC specializes in filter vessels and filter bags, providing the best solution for liquid-solid separation.

PLM Self cleaning filter

Filtration of viscous products Précédent Suivant Made in France Automatic self-cleaning filter for viscous products The PLM automatic self-cleaning scraper filter is an industrial filter